Battery recharging and external power supply

In the modern car manufacturing it is often necessary to test several control units and vehicle functions during production, which in turn leads to an excess load of the vehicle batteries. To avoid that the vehicles are leaving the finish lines with only partly charged batteries the vehicle batteries must be recharged automatically during the test.

As a leading company in the field of battery charger technology NORFI has an extensive background in the conception and realization of stationary and automated solutions in the field battery charger systems. NORFI has developed battery charger units equipped with own-developed conveyor systems and rectification areas. In the NORFI Portfolio you are finding the following solutions:

- Battery charger conveyors for production lines

- Battery charger stations for workstation systems

- External power supply

Battery charger conveyor system

Charger retention during running production

Sometimes It is necessary to charge batteries of the vehicles during assembly, otherwise, the cars are leaving the production with only partly charged batteries and have to be taken to rectification areas for recharging. Connecting the batteries to the charger during assembly helps to avoid this additional work.

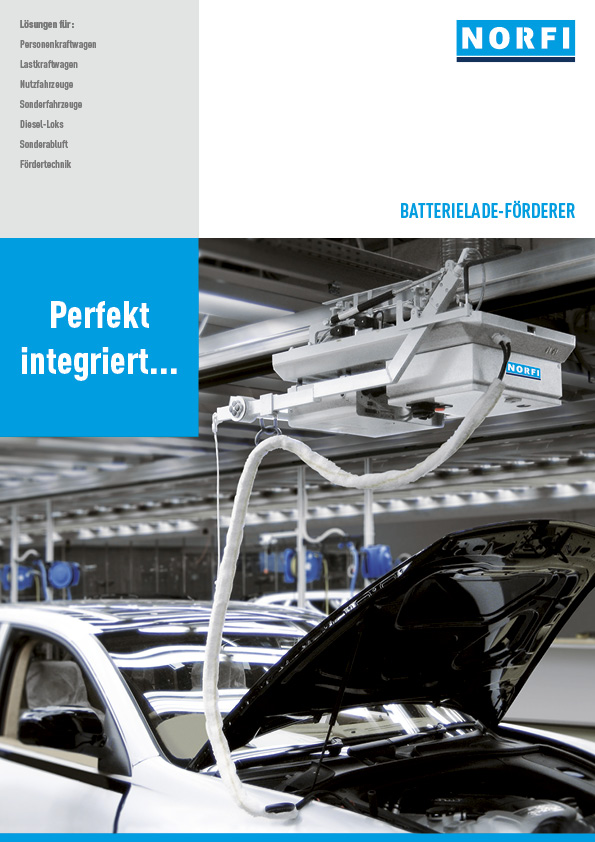

Battery charger conveyor system for production lines

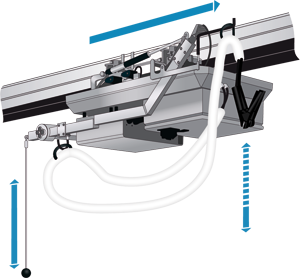

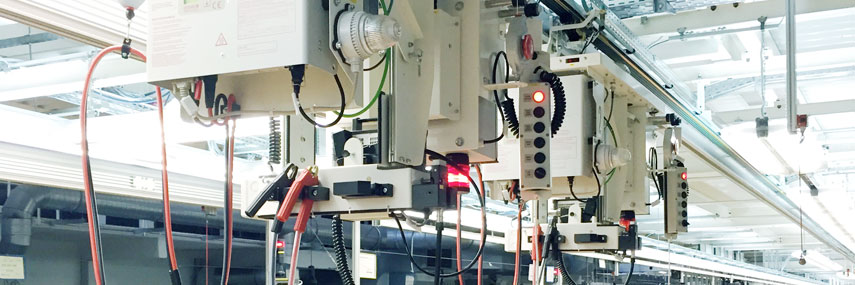

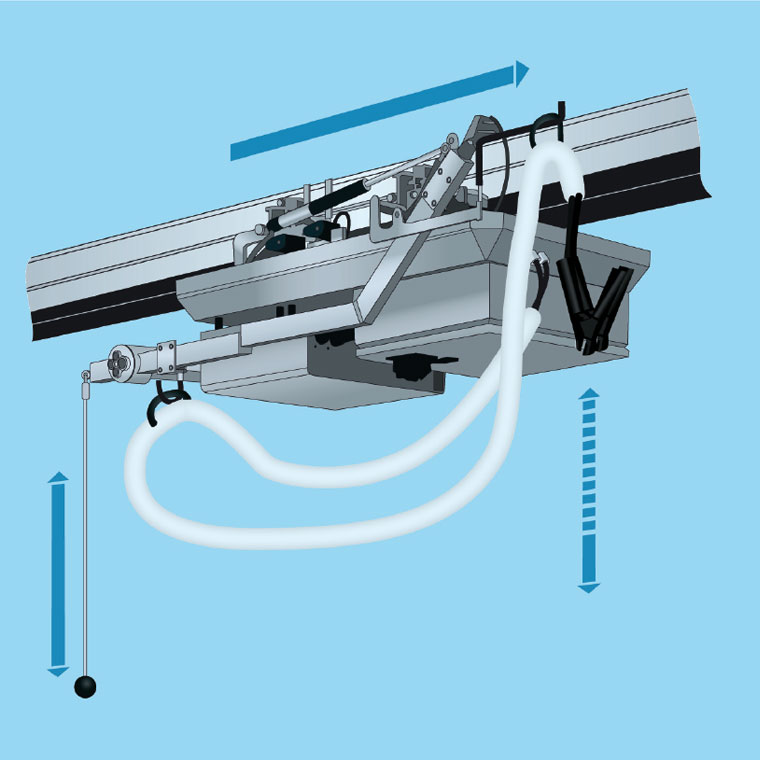

Especially for such applications in the modern automobile industry NORFI has developed the battery charger conveyor system. This revolutionary system permits the commercial battery chargers to move synchronously with the vehicle without having a physical connection to them. Thus, no forces are created during the charging process that could have a negative effect on the vehicle or on the charger cable.

The battery charger conveyor system by NORFI can also be integrated into chain conveyors, electrical overhead tracks, circular conveyors or gravity conveyors. NORFI conveyor systems are of course secured against falling and damaging by means of sensors preventing that conveyor units will frequently collide.

If required, NORFI offers battery charger conveyors with ultrasonic technology. This system consists of single transporting units which are moving along a transport rail mounted above the conveyor belts. Each transport unit is equipped with a self-contained drive and control unit, which is traveling automatically along the transport rail. Special ultrasonic sensors are constantly monitoring the distance between the charger and the vehicle. Their integrated controls permit the carriage to move synchronously with the vehicles.

Battery charger stations

Battery recharging at workstation systems

In the modern car production vehicles are subjected to a series of tests or rectification works at stationary workstations systems. To avoid the discharge of the batteries, a solution is necessary to allow a battery recharging in rectification areas.

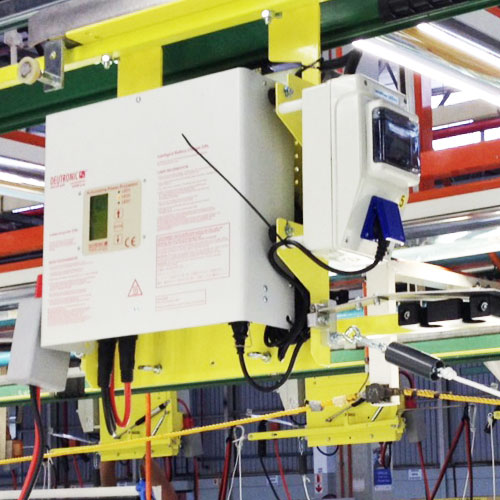

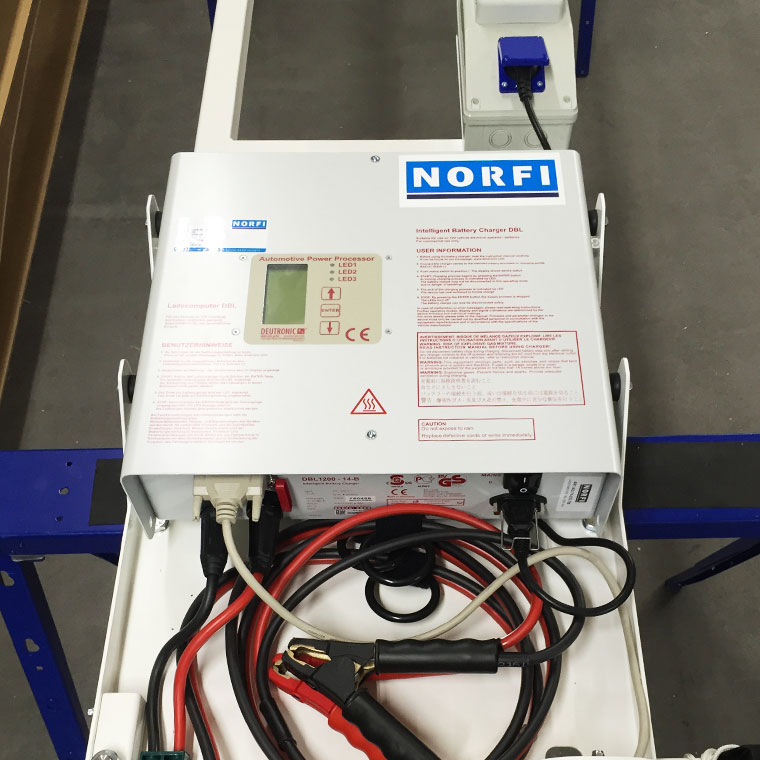

Battery charger stations at rectification work stations

Especially for the demands of rectification work stations in the car production where the vehicles are driven either in boxes or will be lifted on hoists NORFI offers battery charger stations in stationary or movable version. This makes it possible to supply electrical power to the batteries or to recharge them. These system can be reconnected easily and are providing a reliable recharging of the batteries.

NORFI battery charger stations will be mounted according to the workplace layout or by customers demand either above the working areas in suspended version or directly at the hoist.

To fulfil the specific requirements of workshop services NORFI offers battery chargers with intelligent sensors which detect the vehicle and determine the necessary battery charger clamps. Finally, the worker will be asked to connect the charging computer to the batteries.

NORFI battery charger technology in the car production

Battery charger conveyor

Conveyor system for the transport of battery charger devices in the car production

External power supply

External power supply in the car production

The vehicle batteries will be installed only later during the production process. Nevertheless, at early stage of production several test processes will be executed for which an external power supply is necessary. In such situations reliable solutions which supply external power to the vehicle are in demand.

NORFI systems for external power supply

Especially for such situations NORFI has developed solutions for the external power supply. NORFI systems for external power supply are available either in stationary or movable version and permit to work at the vehicles or to start them without any installed batteries.

NORFI systems for external power supply not only allow working at the vehicles without battery, but also guarantee a 99% energy capacity at the end of the car manufacturing process.